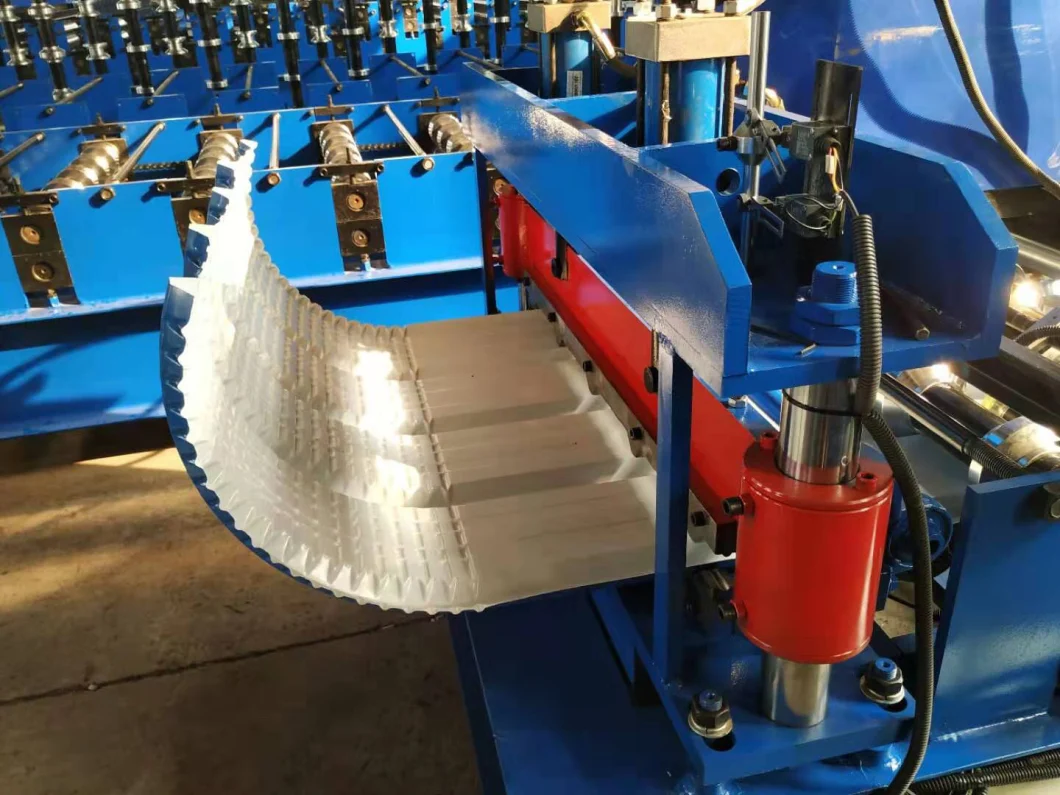

Automatic Tile Glazed Roof Panel Curving Machine

Package size per unit product 500.00cm * 150.00cm * 150.00cm Gross weight per unit product 40.000kg Product Description

Description

Basic Info

| Customized | Customized |

| Usage | Roof, Wall |

| Transmission Method | Hydraulic Pressure |

| Name | Automatic Tile Glazed Roof Panel Curving Machine |

| Materials Thickness | 0.3-0.8mm |

| Raw Materials Width | Based on Roof Machine Design |

| Cutting Blade | Cr 12 High Grade Steel |

| Roller Diameter | 70mm |

| Roller Material | 45#Steel Chrome Plated |

| Shaft Material | High Grade 45# Steel |

| Control System | PLC |

| Suitable Material | Color Galvanizedsteel Coil |

| Main Frame | 350 H Beams |

| Middle Plate | 16mm |

| Weight | 2450kgs |

| Hydraulic Pump | 3kw |

| Main Motor | 3kw |

| Decoiler | 1 Set Manual with Free |

| Transport Package | Main Body Plastic Film, Spare Parts Put Carton Box |

| Specification | 2600*1500*1600mm |

| Trademark | No |

| Origin | China |

| HS Code | 84552210 |

| Production Capacity | 300sets/Months |

Packaging & Delivery

Package size per unit product 500.00cm * 150.00cm * 150.00cm Gross weight per unit product 40.000kgProduct Description

Product Description :Curved roof sheet making machine has different types which used together with a corrugated sheet and IBR sheet, or glazed tile sheet. The curved roof sheet is widely used in many kinds of industrial factories, civilian buildings, and Roof boards for the attached part product It has the advantage of pretty appearance, durable using and so on.

| No. | Automatic Tile Glazed Roof Panel Curving Machine | |

| 1 | Suitable to process | Color alu-zinc steel roof sheet, galvanized roof sheet, aluzinc roof sheet |

| 2 | Roller | 3Rows based on design |

| 3 | Dimensions | 2.6*1.5*1.6m |

| 4 | Motor Power | 3Kw |

| 5 | Pump Station Motor | 3Kw.Lichao Brand |

| 6 | Thickness of the plate | 0.3-0.8mm |

| 7 | Productivity | 3-5m/min |

| 8 | Material of the cutting blade | Cr12, Quenched treatment 58ºC-60ºC |

| 9 | Diameter of the roller | Φ70mm |

| 10 | Weight | About 2450kgs |

| 11 | Main structure of the machine | 350H beams |

| 12 | Processing precision | Within 1.0mm |

| 13 | Side panel of machine | 16mm |

| 14 | Chain Wheel and Cycle Chain | 1 Inch |

| 15 | Voltage | 380V 50Hz 3phases or as customer's need |

| 16 | Control system | PLC control (Delta) |

| 17 | Frequency system | Delta |

| 18 | Drive mode | Motor driver |

| 19 | Touch screen | Delta |

| 20 | Rolling materials | 45# forging steel with chromium plate |

| 21 | Length Tolerance | ±2mm |

Production Flow of Automatic Tile Glazed Roof Panel Curving Machine:

| Passive Decoiler | 1Set |

| Feeding Platform with Pre-cutter | 1Set |

| Roll Forming Machine | 1Set |

| PLC Control System | 1Set |

| Hydraulic Cutting System | 1Set |

| Exit Rack for roofing production | 1Pieces 3Meters |

| Spare parts | One carton box |

Export standard packing of Automatic Tile Glazed Roof Panel Curving Machine:1. The main body of the roll forming machine will be naked packing into the container, covered with plastic film. 2. Steel wire fixes the machine into the container, in case of any damage when shaking on the sea. 3. The spare parts will be packed into the carton box. 4. The received goods table put into a carton box. 5. Manual decoiler naked package.After Sales Service :

1. Warranty: two years, and we will provide technical support for the whole life of the equipment.2. Delivery time: Within 25 days after deposit receipt your payment3. Guarantee period: 24months free service/ pay service all the machine life4. Installation and trainingIf buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train yourworkers/technicians face to face.

FAQ:Q: Are you a trading company or a factory?

A: We are a factory with the professional production team and service consciousness just for exporting various types of cold rollforming machines

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and otherparts, processing, assembly, testing, and packaging on the roll surface and shaft

Q: What can you do if the machine is broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damagedpart, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue throughnegotiation and we provide technical support for the entire life cycle of the device

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy toinstall and have low maintenance requirements

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation

Relative popular sell machines photos showing

Prev: Roofing Accessories Box Barge Cover

Next: China Manufacturer Roofing Sheets Roman Good Price Stone Coated Metal Roof Tiles Accessories

Our Contact

Send now