Ceiling Grid Machine, Light Gauge Steel Framing Machine, Metal Stud and Track Roll Forming Machine

Description

Basic Info

| Model NO. | light keel roll forming machine |

| Automatic Grade | Automatic |

| Capicity of Decoiler | 5000kgs |

| Main Motor Type | Three-Phase Asynchronous |

| Motor Power | 5.5kw |

| Thickness of Raw Material | 0.8-1.2mm |

| Processing Precision | Withint1.0mm |

| Diameter of Main Shaft | 42mm |

| Roller Stations | 12 |

| Transport Package | Main Machine with Film by Container Shipping. |

| Specification | size: about 4.8*1.0*1.3m |

| Trademark | Xinnuo |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 3000 Sets/Year |

Product Description

Company ProfileHebei Xinnuo Roll Forming Machine . located in Botou, enjoying convenient and effective transportation for being close to No.104, 106 national road and having Jinghu, Shihuang high speed way through all the area, is the professional manufacturer of metal sheet cold roll forming machines for about 20 years. We not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purlin machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc. Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good quality.

With the principle of credibility first, mutual benefit and honoring commitment, we can achieve win-win situation.Ceiling Grid Machine, Light Gauge Steel Framing Machine, Metal Stud and Track Roll Forming MachineThis type of C purlin machine is full-automatic, change the sizes with the computer. Just need adjust the cutter with hand.

Technical parameters of roll forming machine:

- Technique parameters of the processing line

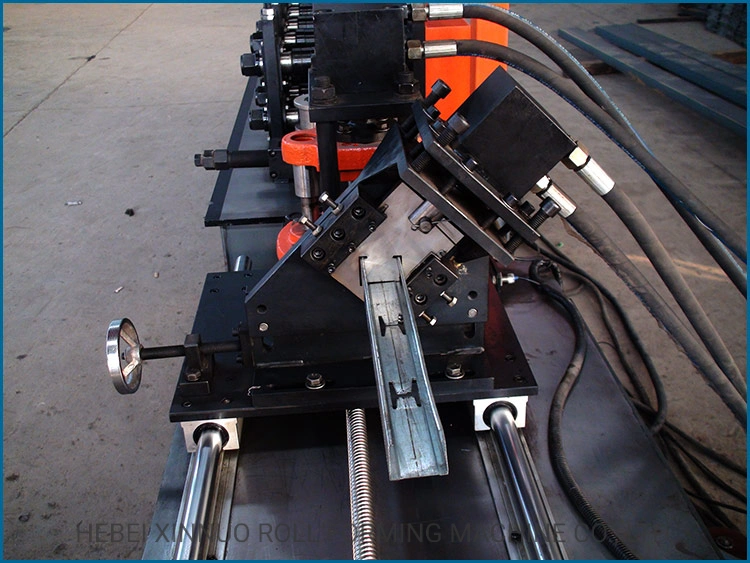

| Main parameters of steel metal stud track channel roll forming machine | ||

| 1 | Suitable to process | steel |

| 2 | Width of the feeding material | Max. 500mm |

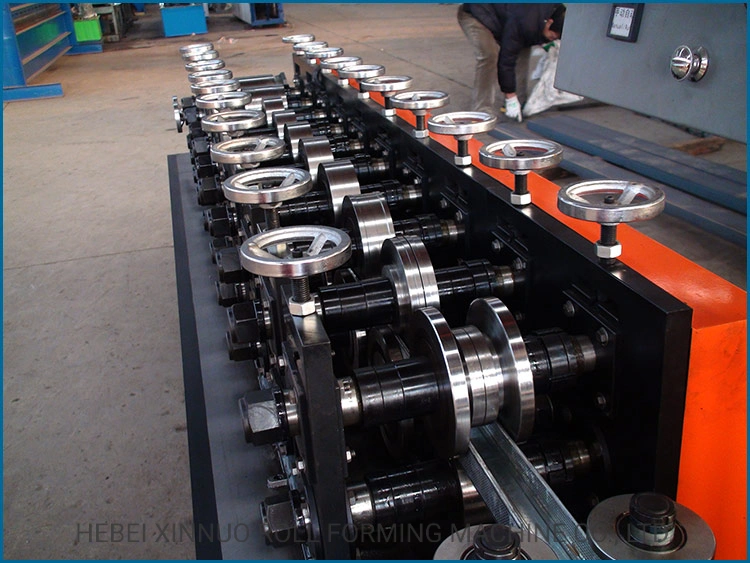

| 3 | Roller station | 12 rows |

| 4 | Thickness of feeding material | 0.8-1.2mm |

| 5 | Productivity | 15-45m/min |

| 6 | Rollers' material | 45# steel |

| 7 | Diameter of shaft | 42mm |

| 8 | Weight | About 2.5T |

| 9 | Size | 4800*1000*1300mm |

| 10 | Voltage | 380V 50HZ 3phases |

| 11 | Main motor power | 5.5 kw |

| 12 | Hydraulic cutting power | 3 kw |

It can handle the entire machine frame or parts,making the rusty surface clean and smooth The surface of the product increases adhesion.

MACHINING

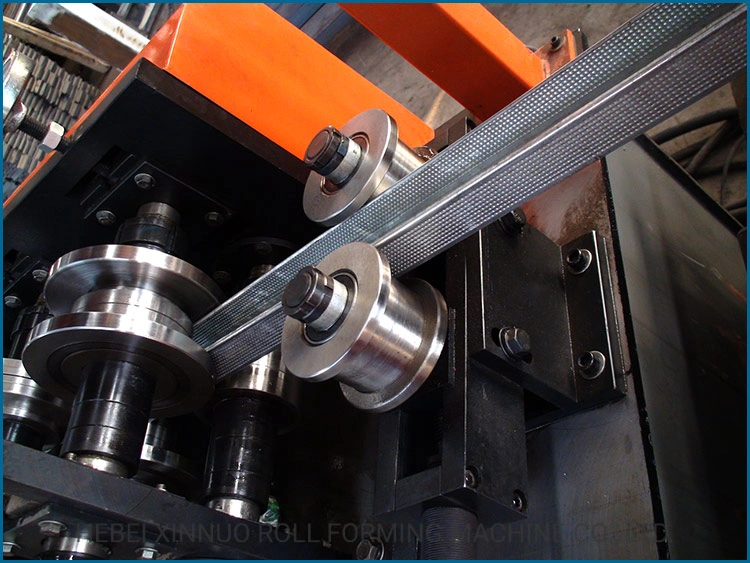

This line, have high precious CNC grinders and milling machines, to make the rollers and shafts of the machine.After produce, have professional engineer to check if these are qualified.

From one roller to one machine, we do every step carefully to make sure the quality.

ELECTRICAL CONTROL

All the control system of our machines we make by ourselves. we have a professional engineer to design and make the control system. This can make sure the after-sale service, when customer have problem with control, we can solve it timely.

Packaging & Shipping

Our Contact