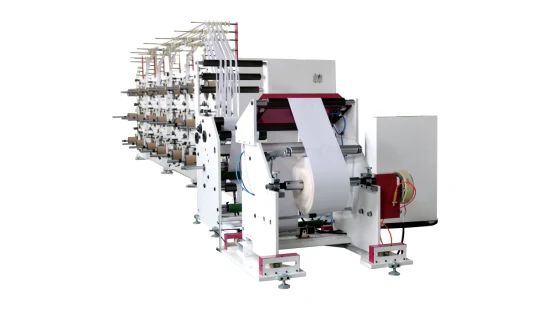

Cheap Factory Price Hot Sale Label Cutting Machine BOPP Film Slitting Machinekraft Paper Converting Machinery Winding Machine

Description

Basic Info

| Model NO. | HH-300I |

| Type | High-Speed Slitting Machine |

| Work Method | Round Knife Cutting |

| Structure | Frame Part |

| Packaging | Case |

| Classification | Slitting Machine |

| Applicable Process | Process Materials |

| Suitable Substrates | Variety Material |

| Packaging Material | Wood |

| Color | White and Red |

| Min.Slitting Width | 1-3mm |

| Max Unwind Diameter | 800mm |

| Max Rewind Diameter | 380mm |

| Machine Speed | 200m/Min |

| Transport Package | Seaworthy Wooden Cases |

| Specification | 6.6*1.8*1.5m |

| Trademark | honghai |

| Origin | China |

| HS Code | 8445111100 |

| Production Capacity | 120 Sets Per Year |

Packaging & Delivery

Package size per unit product 6600.00cm * 1800.00cm * 1660.00cm Gross weight per unit product 7000.000kgProduct Description

Packaging & Delivery

| Package size per unit product | 6.6*1.8*1.5M(L*W*H) |

| Gross weight per unit product | 6.3t |

Application:

Suitable for slitting,spooling and rewing PET,PTFE,EVA foam,foam tape,silicone strip,woven fabric,carry handle tape,paper,electrolytic capacitor paper,cotton paper,aluminum foil,adhesive tape,hand-held tape etc.

Technical Parameters:

| Machine width | 600MM/1000MM |

| Max. Rewind diameter | 380MM |

| Rewind I.D | 3"-6" |

| Max. Unwind diameter | 1000MM |

| Min. Slitting width | 2-5MM |

| Max. Running speed | 100M/Min |

Feature :

1.The Slitting & laminating machine has high precision and high sensitivity.2.The unwinding & rewinding parts use air shaft and tension is controlled by magnetic powder clutch.3.Unwinding correction adopts imported gas-sensitive detection and hydraulic automatic deflection control.4.Automatic detection, automatic correction, automatic meter length can be realized.5.Slitting preparation, fast slitting speed, easy operation and maintenance, etc.

Charatertistics :

The machine is good at slitting the meterial which is difficult to slit and in great variety.

1.EPC system.2.Shear blade/industry knife/air blade/rotary blade slitting.3.Center surface type rewinding.4.Moveable rewind shafts or fixed spool winder shafts(depends on materials)5.PLC calculating for auto tension control.

Optional configuration:

Raw Material Auxiliary Install Raw materials:using hydraulic pressure type power, suitable for unmanned workshop, can save manpower and shorten loading and unloading time.

Receiving device: a platform for connecting front and back materials to improve the flatness of receiving materials and increase the efficiency.

After Sales Service

After-service:

1. Warranty for machine: 12months.2. After-service: A reply within 24 hours.3. A free training in our factory available before delivering machines.

Machine Version

Real photos of the machine

Finished product display

Machine detail picture

FAQ

Q:Are you manufacturer or trader?

A:We are manufactuer

Q:Where is your factory location?

A:Our factory is located in Suzhou city of China.

Q:Can you design or modify the machine according to my requirement?

A:Yes,we can design or modify the machine according to your requirement

Q:What is your payment term?

A:30% advance by T/T,70% balance paid before shipment or L/C at sight

Q:What is the warranty for your machine?

A:Our machine warranty 12 month after installation. We also offer lifetime maintenance

Q:Do you offer installation and training service for your machine?

A:Yes,we can offer installation and operator training.

Our Contact