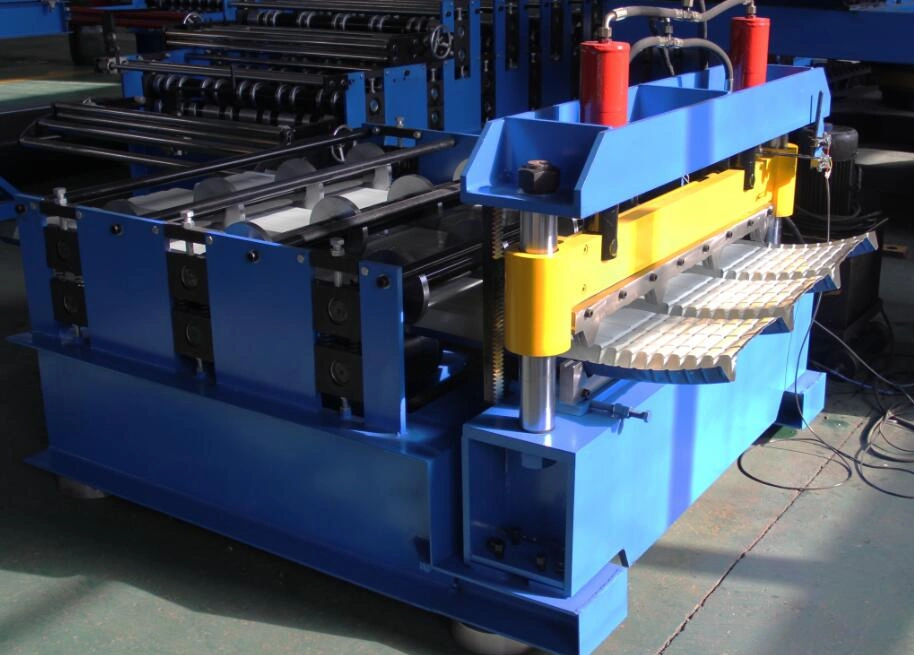

Curving Machine Roofing Panel Steel Metal Crimping Roll Forming Machinery with ISO9001/CE/SGS

Description

Basic Info

| Model NO. | Metal Crimping Roll Forming Machinery |

| Certification | CE, ISO, SGS |

| Condition | New |

| Customized | Customized |

| Usage | Roof, Wall |

| Transmission Method | Chains |

| Material | Gi PPGI Aluminum |

| Thickness | 0.3-0.6mm |

| Type | Metal Crimping Roll Forming Machinery |

| Roller Material | 45# Steel |

| Shaft Material | 45# |

| Voltage | 380V 50Hz, 3pH |

| Speed | 8-12m/Min |

| Control | PLC Control |

| Screen | Text or Touch |

| Serivice | Engineer Installing |

| Frame | 350h |

| Side Plate | 14mm |

| Motor | 4kw |

| Delivery | 30 Working Day |

| Service | 1 Year |

| Transport Package | Fit for Container |

| Specification | IBR MACHINE |

| Trademark | RFM |

| Origin | Hebei China |

| HS Code | 84552210 |

| Production Capacity | 30set/Month |

Packaging & Delivery

Package size per unit product 250.00cm * 135.00cm * 130.00cm Gross weight per unit product 1500.000kgProduct Description

Hydraulic Curve Steel Bending Arch Machine Roofing Sheet Crimping Making Machine Machinery China

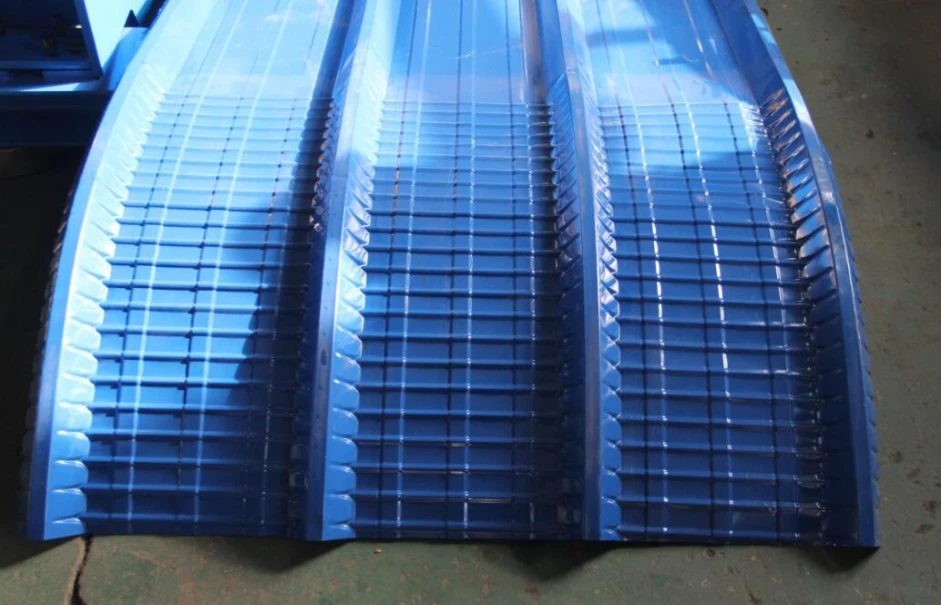

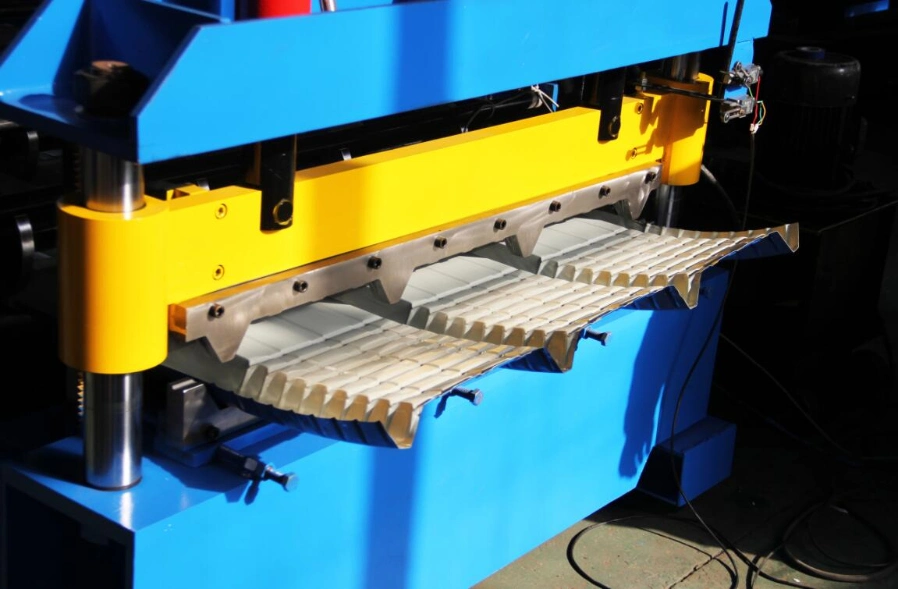

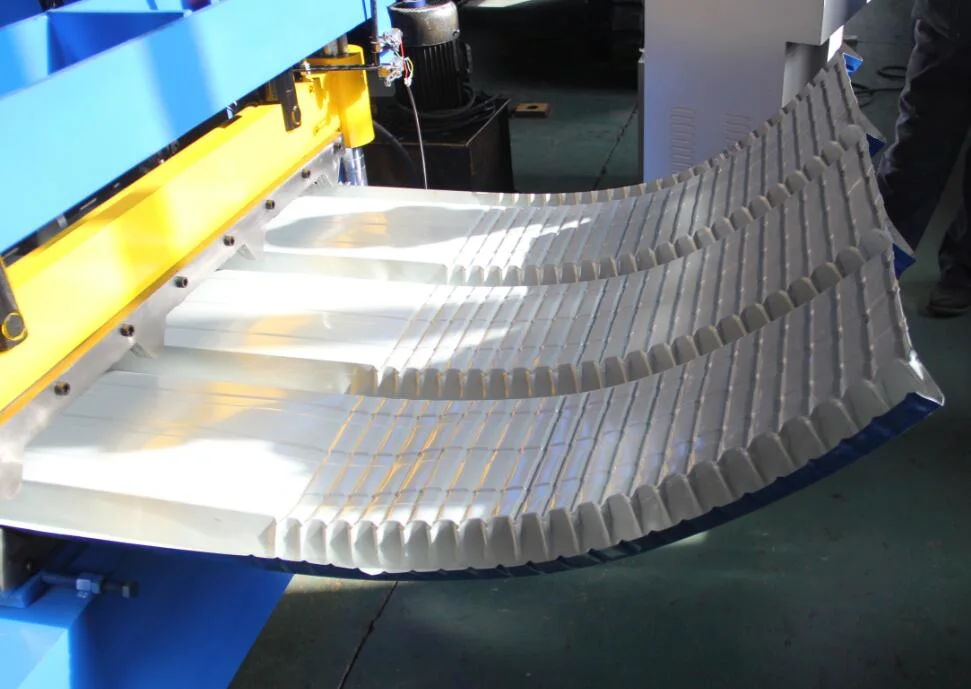

It is used to curve formed corrugated sheet, final product is used as roof of building.

Why choose this curving machine?1. Certificate: ISO 9001, CE,2. Lifetime services3. 72mm diameter solid steel shaft. Roller cover with 0.05mm chrome; Lifetime>10years.4. Introduced Mitsubishi PLC with touch screen to machine controll system.5. One worker operation (minimum) 6. Heat treatment:Cutting blade. Quenched treatment: Cr12 mould steel cutter7. Product cut-to-length.8.Technician overseas installing and training available

Item | Specification | |

| Mterial | Thickness (mm) | 0.4-0.7 |

| Yield strength (mpa) | 235-345 | |

| Roller material | 45#Chrome steel | |

| Motor power | Aabout 3kw | |

| Control mode | Delta PLC | |

Main body of machine is naked and covered by plastic film,loaded into container and steadily fixed in container suitable by

steel rope and lock,suitable for long distance transportation.

1.We can design operation language as customer's request.2.We provide 24 hours on line or video service for customers' any questions.3.We offer technical support for the entire life of our machines.4.We can send our technicians to install and train the workers in clients' factories with extra cost.

4) Company :Main company and branch

FAQ:

---------------------------------------------------------------------------------

A:- What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- About the after-sales service. We can send technician to your country to fix the machine. The buyer should bear all the cost including: visa, Roundtrip ticket and suitable accommodation, also buyer should pay the salary 100USD/day.

The warranty is one year. and we will provide the technical support for the whole life. It is free to maintain the machine the first year after buying, including changing the main components. The first year hence, you will pay for our technician $50 per day to maintain the machine. And the components are not free, if you need to get it from us.

E:- Any other service?

- We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

Prev: Hydraulic Roof Curving Bending Forming Machine Provide Customized Services

Next: Metal Arch Roofing Sheet Curving Roll Forming Machine for Sale

Our Contact