Metal Roofing Sheet Standing Seam Bemo Sheet Profile Roll Former Line Machine With PLC Control System

Description

Basic Info

| Customized | Customized |

| Advantage | Use Widely |

| Condition | New |

| Material Thickness | 0.4 - 1.5 mm |

| Production Speed | 10 - 20 M/Min |

| Material | PPGI, Aluminum sheet, Aluminum-galvanized sheet |

| Electrical Control | PLC |

| Transport Package | Wood Box |

| Trademark | TGMCO |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 50 Sets/Year |

Product Description

Welcome to Taicang Global Machinery https://global-machinery1.en.made-in-china.com/At Global Machinery, we provide Tube Mill, Roll Forming Machine, Slitting & Cut to length Line and corresponding components, and meet your customized requirements. Contact us right now!

Summary

Standing seam is an economical, snap-together roofing system, for commercial and residential applications. Standing seam roof Roll Forming Machine is special designed for its production.

Main Specification

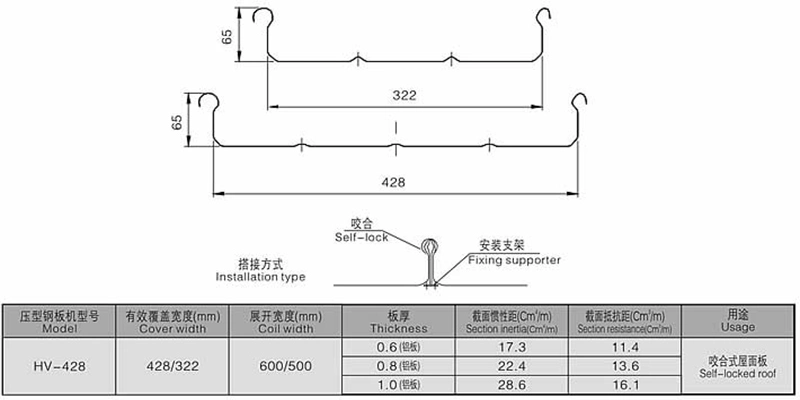

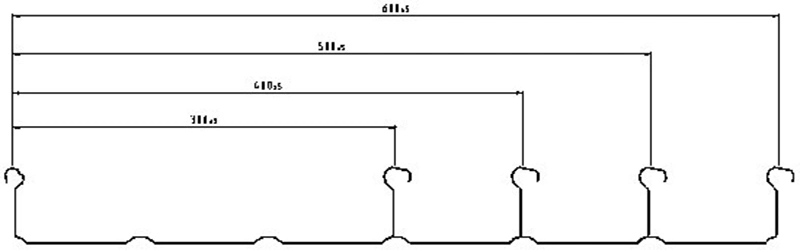

1. Suitable Material: Pre-painted sheet, aluminium sheet, Galvalume2. Material Width: Max. 680mm, As per profile3. Material Thickness: 0.40 - 0.80 mm Pre-painted sheet; 0.70-1.20 aluminium sheet

| Coil Width | As per drawing |

| Suitable Material | PPGI, Aluminum sheet, Galvalume |

| Thickness | 0.4 - 1.5 mm |

| Working Speed | 10 - 20 m/min |

| Electrical Contral | PLC(Panasonic, Simens) |

| Main motor power: | 75kw |

Equipment List

1. Hydraulic Decoiler with Breaking device is equipped for coil processing.2. Rollformer with fourteen rolling station forming process3. Hydraulic cut-off machine4. Run Out Table or automatic stacking device5. Mitsubishi (Japan) PLC and Touchable Screen are used for data processing and setting.6. Roll forming speed is 10- 20 meter / minute.7. Automatic seamer

Certificate

Main Customers

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided). We have cooperated with many customers all over the world with high market reputation, no worries.2) Q: How to choose the Tube Mill Line? A: You have to inform us following details:- The pipe material- Round pipe range - Square pipe range - Rectangle pipe range - Wall thickness range- The pipe usage3) Q: How to choose the Roll Forming Machine? A: You have to inform us following details:- Coil material- Coil thickness- Coil weight- Cutting type- Profiles drawings - Other special attention 4) Q: How to choose the Slitting Line & Cut to Length line? A: You have to inform us following details:- Coil material- Coil thickness - Coil width- Coil weight- Finished sizes- Other special attention55) Q: Where is the nearest airport to your company? A: Shanghai Putong or Hongqiao Airport.6) Q: How about your service? A: Before sales: - Technical Support: TGMCO will provide detailed technical information such as technical & commercial offer, machine photos, running video, layout, operation manual, and show you working machines in our factory.- Apply Visa: TGMCO will provide officially invitation letter to apply Visa in china embassy as authority procedures and requirements.After sales: TGMCO provides comprehensive After Sales Support and Service to meet our customer need.- Drawings: Provide the foundation drawing, electric scheme and wiring diagram, hydraulic drawing, pneumatic & electric pipeline drawing and other drawings requested by customer.- Installation and commissioning: TGMCO will send our technicians to customer's workshop for supervision of installation and commissionTraining of Customers' technician/workers during commission- Breakdown Support: We offer 1 year warranty service for main crucial components except consumablesInform immediate technical assistance and advice to customer by phone or e-mail.Skilled and experienced engineers are capable of dealing with any type of breakdowns.Technical service work performed in Customer's site if required.Urgently supply mechanical or electronic components.Fast supply of spare parts and wearing parts to cover foreseeable requirements

Packing & Delivery

Not only the Good Machine, but also the Most Attentive ServiceIntegrity Solution & Turnkey ProjectCreat the Value of Steel

Our Contact