Metal Steel Framing Profile Structure Building Warehouse Automatic Changed CZ Purlin Hole Punch Cold Roll Forming Making Machine for Prefabricated House

Main Features Of Quickly Change CZ Purlin MachineADVANTAGES: 1. PLC CONTROL C/Z INTERCHANGEABLE, EASY ACESS, SIMPLE TO L

Description

Basic Info

| Model NO. | CZ Purlin Roll Forming Machine |

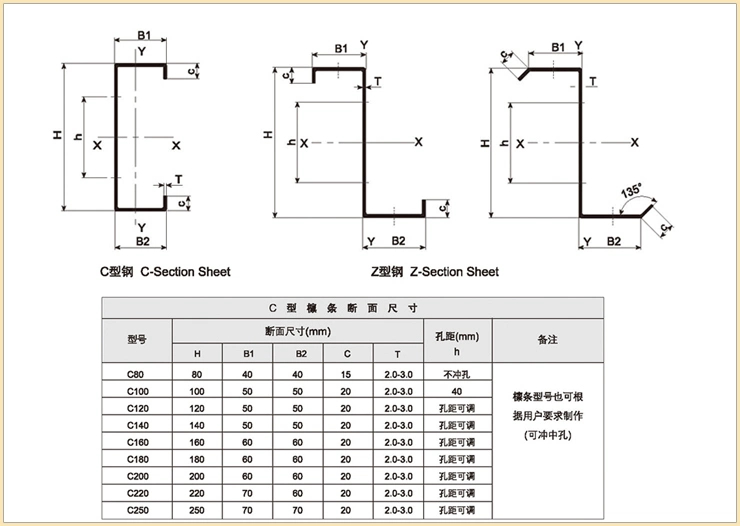

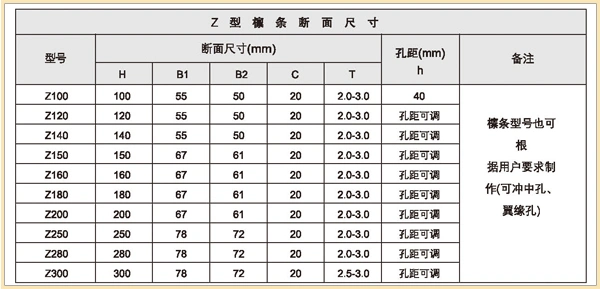

| Size | C80-C250/Z120-Z300 |

| Material | Galvanized Sheet |

| Raw Material Thickness | 1.5 mm-3.0 mm |

| Yield Strength | 235/345 MPa |

| Roll Forming Machine Shaft Material | Cr12, Heat Treatment |

| Roller Material | Cr12, Heat Treatment |

| Cutting Blade | Cr12MOV After Heat Treatment |

| Voltage | 380V, 50Hz, 3phase, as Your Request |

| Control System | Computer Control |

| Screen | Touch Screen |

| PLC | Siemens |

| Touch Screen | Siemens |

| Encoder | Omron |

| Transport Package | 40HP+20gp, Machine Wrapped with Waterproof Cloth |

| Specification | 20T |

| Trademark | Xiamen Liming |

| Origin | Fujian, China(Mainland) |

| Production Capacity | 50 Set/Month |

Product Description

Main Features Of Quickly Change CZ Purlin MachineADVANTAGES: 1. PLC CONTROL C/Z INTERCHANGEABLE, EASY ACESS, SIMPLE TO LEARN, LOWERS LABLE COST.PRODUCE DIFFERENT SIZE PURLIN WITHOUT MANUAL CHANGING ROLLERS OR SPACERS.2. FORMING WITH PRE STRENTHENING, TO MAKE SURE THE PERFECT SHAPE3. INFINITE SIZE CUTTER THAT CHAGES SIZES WITH A FEW SPIN.4. EASY OPERATION, LOW MAINTENANCE COST.5. WITH PRE-CUT SYSTEM SAVES MATERIAL.6. C/Z INTERCHANGED WITH ONE BOTTON Prpfile

General Parameter

| 1 | Item | Parameters |

| 2 | Size | C80-C250/Z100-Z300 |

| 3 | Material | Galvanized Sheet |

| 4 | Thickness | 1.5-3.0 mm |

| 5 | Yield Strength | 235/345 MPa |

| 6 | Feed Width | According to the profile |

| 7 | Max. Line Speed Of Roll Former | Approx.30 m/min |

| 8 | Roll Stages | 20 Stages |

| 9 | Main Motor Power | 30 KW (Servo Motor) |

| 10 | Hydraulic Group Power | 15 KW |

| 11 | Total Power | 45 KW |

| 12 | Electric Standard | AC380V,50Hz,3Ph |

| 13 | Machine Dimensions | 11840*1840*2220 |

| 14 | Total Weight | Approx. 20T |

Machine Components

1. Hydraulic Pre-cutting (used for cutting coil head and coil tail) Function: Cut material head and tail to reduce waste. Blade: scissor cutting structure, stable and convenient feeding. Material: Cr12mov, Heat Treatment, and Shear all the way up to 3.0mm Steel Plate.

2. Pre-Leveling DeviceThe In-feed Section of the machine allows for variations in sheet width.Pre-Level Device with 4 over 3 shafts to remove the Coil-set.Making sure the material is flat enough to be formed (or punched).3. HYDRAULIC PRE-SHEARING & Pre-punching devicePunching die material: Cr12 with Heat Treatment, more reliable, higher hardness. On line Die-set LEAD screw drive for different web punching sizes, and the number of punching cylinders could be customized upon client needs(CUSTOMIZABLE).Pre-shearing is used when changing the coil, manual control, only for cutting the first piece and the end piece of the sheetPre-cutting device, PLC control, purlin has bit open-up in both ends; panel length min 2.5m.4. Cold Rolling MillsHigh Precision Servo Motor is adopted to ensure the punching accuracy.One-button control to swap from C to Z, Z to C.Changing WEB and FLANGE with auto PLC control,any within range.Shaft Diameter:Φ75/95 mm .Raw Materials: Cr12, Heat Treatment.

5.Hydraulic Post CuttingScrew adjustment to realize rapid switching of WEB size, to achieve different specifications of C/Z purlin shearing.The cutting tool material is made of Cr12MoV after heat treatment, with high strength, which can better guarantee the cutting effect and the durability of the cutting tool. Blanking size up to 8mm, Minimize the material wastes.

6.PLC Control System Fully automatic conversion control, Size: C to Z or Z to CSpecification: C100-C300/Z120-Z300Fully automatic production: QUANTITY/ PRODUCT LENGTH/PUNCHING POSITION/ (UPTO 100 ORDER MEMORIES).PLC(Siemens), Touch Screen (Siemens), Encoder (Omron), etc.Cut-to-length-tolerance≤±1mm

Prev: Peb Steel Construction Automatic Change CZ Purlin Roll Forming Machine

Next: Cheap Factory Price Full Automatic Changeable CZ Purlin Steel Cold Roll Forming Machine with PLC

Our Contact

Send now