Pinch Plate Clip Lock Standing Seam Roofing Sheet Profiling Roll Forming Machine

Description

Basic Info

| Model NO. | FX110 |

| Name | Pinch Plate Roll Forming Machine |

| Roller | 45# Steel with Quenching |

| Shaft | 45# Steel |

| Diameter | 50mm |

| Chain | 1 Inch |

| PLC | Delta |

| Motor | 4kw |

| Pump | 3kw |

| Speed | 15m/Min |

| Warranty | 2 Years |

| Transport Package | Standard |

| Specification | As design |

| Trademark | RFM |

| Origin | Hebei China |

| HS Code | 84552210 |

| Production Capacity | 1000sets/Year |

Product Description

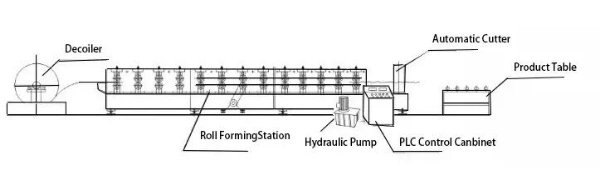

Pinch Plate Clip Lock Standing Seam Roofing Sheet Profiling Roll Forming MachineWorking flaw chart

Pinch Plate Clip Lock Standing Seam Roofing Sheet Profiling Roll Forming Machine adopts high-level automatic

control software, and the color steel tile press realizes production information management. Easy operate Automatic

control Simple maintenance Hydraulic cutting High accuracy Quality bearing

Technical parameters

Clip Lock Standing Seam Roofing Sheet Profiling Roll Forming Machine | |

Suitable raw material | PPGI/PPGL/GI/GL Steel Coils |

Thickness of coil sheet | 0.3-0.8mm |

Feeding Coil width | 914mm |

Effective width | 685mm |

Under frame | 400H-beam |

Diameter of Soild shaft | 70mm, high grade 45# steel, finish turning, cylindrical grinding, with keyway |

Roller | High grade 45# steel, processed by CNC lathe, Quenched and tempered treatment, hard chrome coated 0.05-0.07mm |

Thickness of middle plate | 16mm |

Forming stations | 25 |

Drive type | By chain(1.0 inch) link bearing model 6210 |

Power of main motor | 7.5kw with Cycloidal reducer, Lichao, Shanghai |

Power of pump station | 4kw, Lichao, Shanghai |

Forming speed | About 15-20m/min |

Hydraulic cutting | Controlled by PLC |

PLC | DELTA, TAIWAN / Mitsubishi, Japan |

We have a team of skilled engineers and one group for after-sale service.

The customer can find us in China or aboard.

We go aboard 2-3 times each year to participate exhibition and visit customers.

Standard export packing and delivery

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Our Contact