Polycarbonte PC Greca Rainbow Modular Cellular Multiwall Hollow Roofing Sheet Panel Extrusion Line Extruder Machine

Double Wall/Triple Wall/Multiwall Polycarbonte PC hollow roofing Sheet Extrusion Line extruder machine This extrusion li

Description

Basic Info

| Model NO. | LSJ-120/35+45/30 |

| Product Type | PC Board |

| Board Layers | Single Plate |

| Screw No. | Single-screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Condition | New |

| Sheet Size | 2100mm Width*4-10mm Thickness |

| Application | Sunshine Panel Roofing or Construction etc |

| Extruder Model | Sj120/35+45/30 |

| T-Die Head | Jc-Times Brand |

| Max Capacity | 350kg/H |

| Total Installed Power | 510kw |

| Main Electrical Parts | ABB, Omron, Rkc, Schneider, Siemens etc |

| Guaranteed Time | 12 Months |

| Transportation | 4 Sets of 40gp Containers |

| Transport Package | Wooden Pallet/Cases with Streching Films |

| Specification | CE, ISO9001-2008, SGS, GOST |

| Trademark | leader machinery |

| Origin | Qingdao, China |

| HS Code | 84772090 |

| Production Capacity | 50 Sets/Per Year |

Product Description

Double Wall/Triple Wall/Multiwall Polycarbonte PC hollow roofing Sheet Extrusion Line extruder machineThis extrusion line consists of single screw extruder, melt-pump, hydraulic filter exchanging unit, hollow sheet die head, vacuum calibrating table, first haul off machine, oven, corona treating unit, cooling table, second haul off machine, trimming and length-settled cutting units and stacker etc.Characteristics of vacuum calibrator:1. High quality mould steel or high strength Al-Mg Alloy2. Special harden treatment and non-sticky coating on the surface.3. Independently controlled vacuumize device and temperature controlling system.4. Consist of vacuum sealing edge device. The technology of hollow sheet die with co-extrusion feed block to get UV+PC+UV, UV+PC hollow sheet can save 30% UV on the surface.Hollow Sheets Specifications:

Sheet width: 600mm-700mm-1050mm- 1220mm-2100mm-2300mm,

Sheet thickness is 4mm-6mm-8mm-10mm-12mm.

Sheet walls: double walls , three walls, 4 walls and more etc.

Application:1) Sunshades for stadium and bus shelters2) Lighting for corridors, passages and subway entries 3) Bank ATMs4) Sound and heat insulation for construction such as: houses 5) Canopies for agriculture greenhouse, zoos6) PC sheets mainly used for building and decorating materials, greenhouse material, telephone booth, insulation shield express ways & highways7) Office building, hotels, villas, stadium, schools, bus stop, terminals, hospitals, subway entry and exit doors, etc.

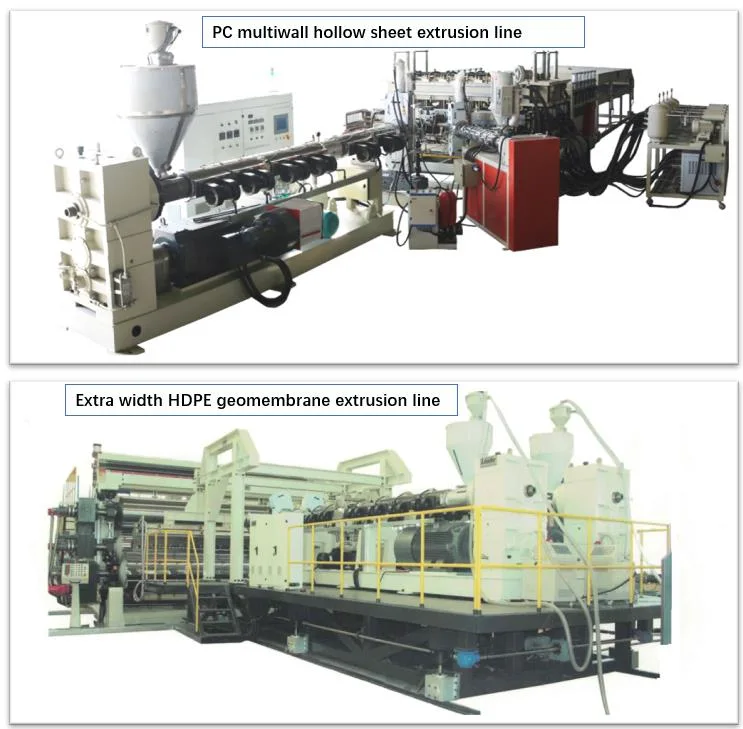

MACHINE PICTURES:

PART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

PART 6 OUR RELIABLE SUPPLIERS:

PART 7 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

PART 9 Contact Information:

PART 10 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

Best regards!

Sincerely yours,

Lilly Zhou, Sales Manager

Qingdao Leader Machinery

Address: South of Yangjialin, Beiguan, Jiaozhou, Qingdao, China

Postal No.: 266300

Tel/fax: 0086-532-86620998, 86622373, 82278979

Website: http://extruder-cn.en.made-in-china.com

Our Contact

Send now