Profiles Door Window Equipment Sheet Metal Hydraulic Curving Roll Forming Machine

Description

Basic Info

| After-sales Service | 1 Year |

| Warranty | 1 Year |

| Tile Type | Colored Steel |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

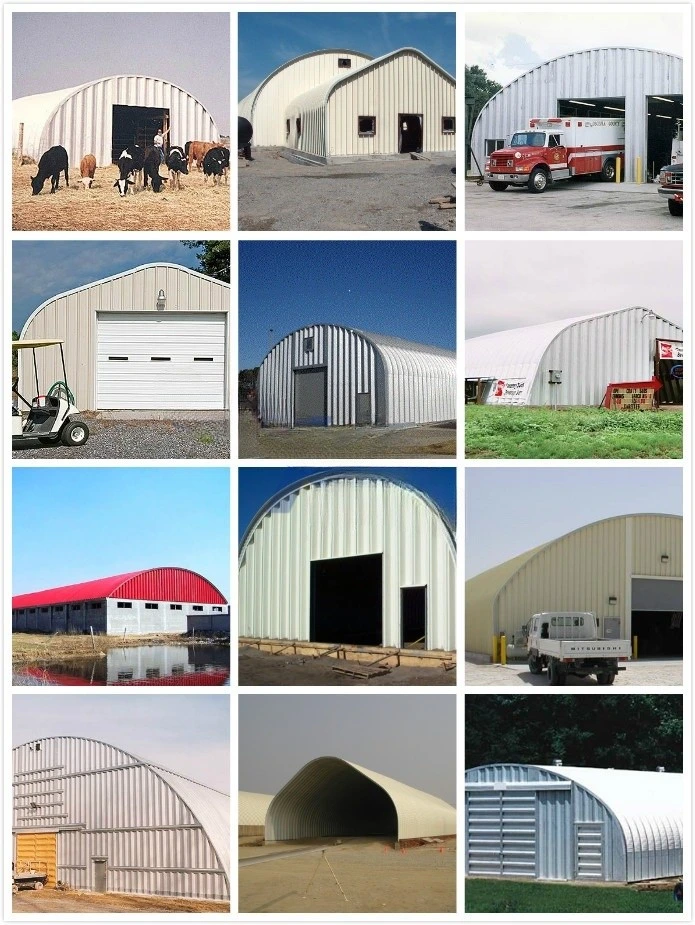

| Usage | Roof, Wall, Floor |

| Transmission Method | Electric |

| Transport Package | Standard Export Package |

| Specification | 1800*1200*1400mm |

| Trademark | ZHONGKE |

| Origin | Botou |

| HS Code | 8455221000 |

| Production Capacity | 30sets/Month |

Packaging & Delivery

Package size per unit product 180.00cm * 120.00cm * 140.00cm Gross weight per unit product 2000.000kgProduct Description

Product Description

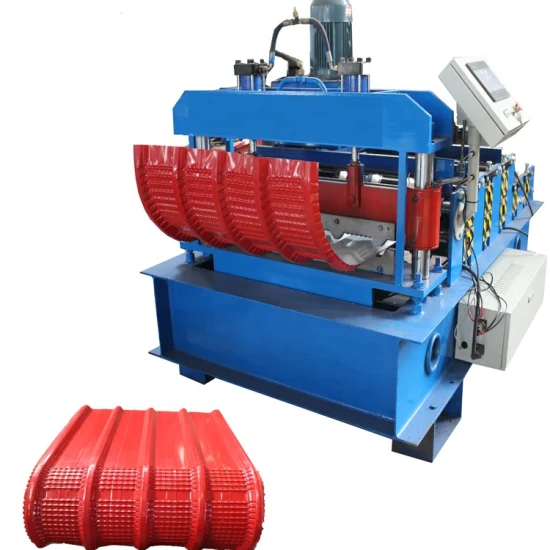

Profiles door window equipment sheet metal hydraulic curving roll forming machine

| Part details | Item Name | Specification |

| Material | Raw material | Color steel |

| Thickness | 0.3-0.8 mm | |

| Machine | Roller station | 3 |

| Shaft diameter | 70 mm | |

| Shaft material | 45# steel with 0.05mm chrome | |

| Roller material hardness 30-40 HRC | 45# steel with 0.05mm chrome | |

| Machine size | About 1.8×1.4×1.7 m | |

| Machine weight | About 1.2 ton | |

| Machine color | As customer' request | |

| Working speed | 3-8 m/min | |

| Power | Driving way | Chain 1 inch |

| Main power | 3 kw | |

| Voltage | 380v/50HZ,3P or customizeas customer' request |

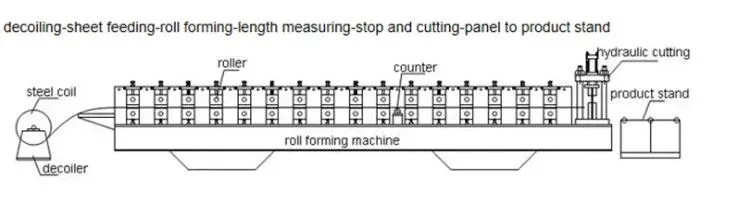

Process Drawing

Company Profile

Our factory is a professional Roll Forming Machine manufacturer with 17 years experience,we have 100 well trained workers and 20,000m'(square meters) workshops.Specializing in the production of various types of tile press equipment,the development and production of automatic intelligent control tile press equipment production line, C type steel, dust collector anode plate and other equipment.Our factory can design and produce various special-shaped cold-bending forming equipment according to the different needs of users.Why Choose Us

Horizontal curve machineHorizontal automatic crimping machine can curve to your want shape and length automatically. Speed about 3-8 m/min, material use PPGI material thickness between 0.3-0.8 mm, machine details is like up type.Bending machineHydraulic bending machine control by foot, it can bend many degree, more flexible and easy operate. Price cheap, bending machine width common include 2m, 4m, 6m and 8m, material use PPGI or GI material, thickness between 0.3-0.8 mm, machine details is like up type.

Our Customers

Packaging & Shipping

FAQ

Q: Can one machine only produce one size?

A: Not exactly, it depends on the machine

Q: Do you have after-sales support?

A: Yes, we are happy to give advice and also have skilled techniciansavailable to maintain the machine if needed

Q: How to visit your company?

A: We can pick you up from Shanghai or Hangzhou airport. Or railwaystation Shaoxing North

Q: What can you do if the machine is broken?

A: Our machine's warranty period is 12months. if the broken parts can'trepair, we can send the new parts to replace the broken parts, butyou need to pay the express cost by yourself. if after the warrantyperiod, we can through negotiation for solving the problems, and wesupply the technical support for the whole life of the equipment

Q: Can you be responsible for transport?

A: Yes, please tell us the destination port or address. we have rich expe-rience in transport

Q: You are a trade company or factory?

A: We are a Manufacturer

Q: Why your price is higher than others?

A: As we persist on that each factory should put quality in the first place.We spend time and money on developing how to make machinesmuch more automatic, accurate, and high quality. We can make surethat our machine could use more than 20 years without any problem

Q: Do you have overseas engineers?

A: Yes, we not only provide overseas engineers but also provide techni-cal training

Q: Do you provide customized?

A: Sure, we can design the equipment according to the data of thestructural section you provide. We are a professional sheet metalforming machine designer and manufacturer.

Our Contact