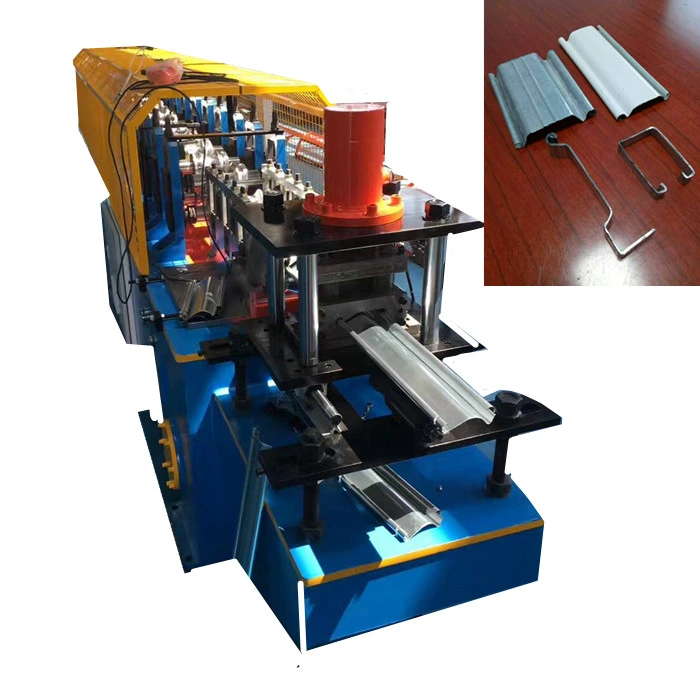

Rolling Shutter Door Forming Machine

Description

Basic Info

| Model NO. | rolling shutter door |

| Forming Stations | 10 |

| Power | 5.5+4kw |

| Voltage | 380V |

| Control System | PLC Control |

| PLC Brand | Panasonic /Mitsubishi |

| Type | PU Shutter Door Machine |

| Method | Assembling |

| Processing | CNC Processing |

| Color of Machine | Blue or as Your Request |

| Transport Package | According to Customers′ Request |

| Specification | Jcx |

| Trademark | JCX |

| Origin | China Hebei |

| HS Code | 8455211000 |

| Production Capacity | 20sets Per Month |

Product Description

Rolling shutter doors forming machine

A Roller shutter door forming machine is designed to produce horizontal roller shutter door slats out of galvanized or prepainted steel.The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously

Shutter door are used a lot for shops and workshops.A rolling shutter door or roller shutter door is a type of door that consists of many horizontal slats hinge together and the door opens and closes by raising up or lowering down along a rolling shutter door track or guide rails.

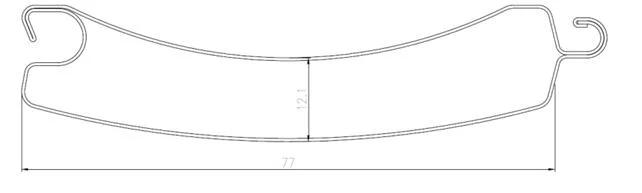

1.Profile of shutter door design:

2.Working process of rolling up door forming machine

3.Technical details:

1.Un-coilerCapacity: 3 tons

Material: #45 steel quenched

Power:2.2KW,03 Phase, 220/380V, 50HZ/60HZ

Method of open and close of segments: manual

Number of segments:4 pieces

Range of segment expansion: ø480- ø520

Inner diameter of coil: ø508

Maximum outer diameter of coil: ø1,300

Feeding speed:25m/min(transducer control)

2.Main roll former

Stations: 12

Rollers material: CR 15, HRC 60. Chrome coated: 0.03-0.05mm, Strength (MPA): 70 tons, 800 MPA

Shaft: diameter 50mm, material is #45 steel. Quenched hot treatment. Strength of the main shaft (MPA): 70 tons, 650MPA

Bearing brand: FAG Germany

Main motor: 7.5KW, 380/220V, 50/60HZ, 3 Phases (OMD Brand)

Transmission by gear

Station material: cast steel

Machine is equipped with cooling system

3.PLC control cabinet

Touch screen brand: Delta

PLC brand: Siemens

Inverter brand: Siemens

Main components for low pressure electricity: Schneider Germany

Encoder: Omron

Sensor: Balluff B+F brand

Control motion/production process: Un-Coiler---12 stations roll forming machine---Hydraulic cutting by servo---output table

4.Cutting platform

Cutting type: hydraulic cutting with servo motor

The material of knives: CR12MOV; heat treatment HRC 55-60, Quenched; the Strength in MPA: 950

Servo motor: 1.5KW, 220V

Tolerance of length: ±0.5mm

Action: the host does not stop, servo track to cut off

5.Hydraulic Station parameter

Hydraulic Motor: 5.5KW, 220V/380V, 50HZ/60HZ, 3 Phases, Siemens brand

Hydraulic pump: Yuken brand Taiwan

Hydraulic valve: Rexroth Germany

Hydraulic cylinder: China

The Hydraulic station have Accumulator

The stations have 1 valves

6.Output table

Length: 8 meters

Drive type: rollers

7.Input material

Material: galvanized sheet

Galvanized steel: 0.8-1.0mm

8.Dimension (L*W*H)

Roll forming machine space: 6.4m*1.55m*1.36m

Working space:12m*3m*3m

9.Working speed

15-18m/min (including cutting)

10.Include the following normal consumable spares

Bearing in main shaft: 10 pcs

Other bearing (sub-rollers): a few

Limit switch:2 pcs

Low pressure electricity: a few

Relay:8 pcs

Oil tube: 2 pcs for each tool

Connector: a few

Cutting knives: 2 extra

Upper shaft and down shaft: 2 pieces

Station: 1 pieces

Gear: 2 pieces

Prev: China Best Automatic Tube Folding Machine / Hydraulic Curving Machine / CNC Pipe Bending Machine

Next: Factory Supply 5 Axis CNC 3D Wood Curving Machine / 5 Axis Wood Carving Machine

Our Contact