Manual Metal Bemo Standing Seam Roof Panel Curving Machine

Package size per unit product 700.00cm * 150.00cm * 150.00cm Gross weight per unit product 4800.000kg Products showing D

Description

Basic Info

| Model NO. | HX |

| Condition | New |

| Customized | Customized |

| Usage | Roof |

| Transmission Method | Hydraulic Pressure |

| Raw Material | PPGI |

| Usag | Steel Construction |

| Roller Material | 45#Steel Chrome Plated |

| Shaft Material | 70mm/75mm(Depend on Different Design) |

| Control System | PLC |

| Color | Blue |

| Thickness | 0.3--0.8mm |

| Application | Construction Panel |

| Main Frame | 350h Steel |

| Operate Style | Semi |

| Lanuage | Chinese, English |

| Motor Brand | China Famous Brand |

| Function | Color Stone Roof Tile |

| Cutting System | Automatic Hydyaulic Cutting |

| Profiles | One Profile |

| Transport Package | Container |

| Specification | 20CBM |

| Trademark | HX |

| Origin | China |

| HS Code | 84552210 |

| Production Capacity | 300set/Month |

Packaging & Delivery

Package size per unit product 700.00cm * 150.00cm * 150.00cm Gross weight per unit product 4800.000kgProduct Description

Manual Metal Bemo Standing Seam Roof Panel Curving machine Technical parameters: | |||

| 1 | Cutting&Hydraulic type | Cut slide/ Double guide pillar | |

| 2 | Hydraulic motor power | 3kw-7.5kw | |

| 3 | Cutting drive | Decelerating motor + Chain drive gear all by high-frequency | |

| 4 | Length measurement | Encoder | |

| 5 | Control System | Panasonic /Siemens / Schneider / Delta PLC | |

| 6 | Chain Size | 1inch/2inch | |

| 7 | Main Frame | 300mm/350mm H-Beam or 350mm | |

| 8 | Backboard Thickness | 17mm/200mm | |

| 9 | Feeding Material | Better as your drawing or from our designer | |

| 10 | Feeding Thickness | 0.18mm-0.8mm | |

| 11 | Effective width | Better as your drawing or from our designer | |

| 12 | Productivity | 8-12/min | |

| 13 | Roll Station | 14rows(according to different design) | |

| 14 | Roller Diameter | 70mm/75mm(depend on different design) | |

| 15 | Roller material | 45# steel | |

| 16 | Cutter material | Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees | |

| 17 | Overall Size | Size of our designer | |

| 18 | Total Weight | 2t-12t | |

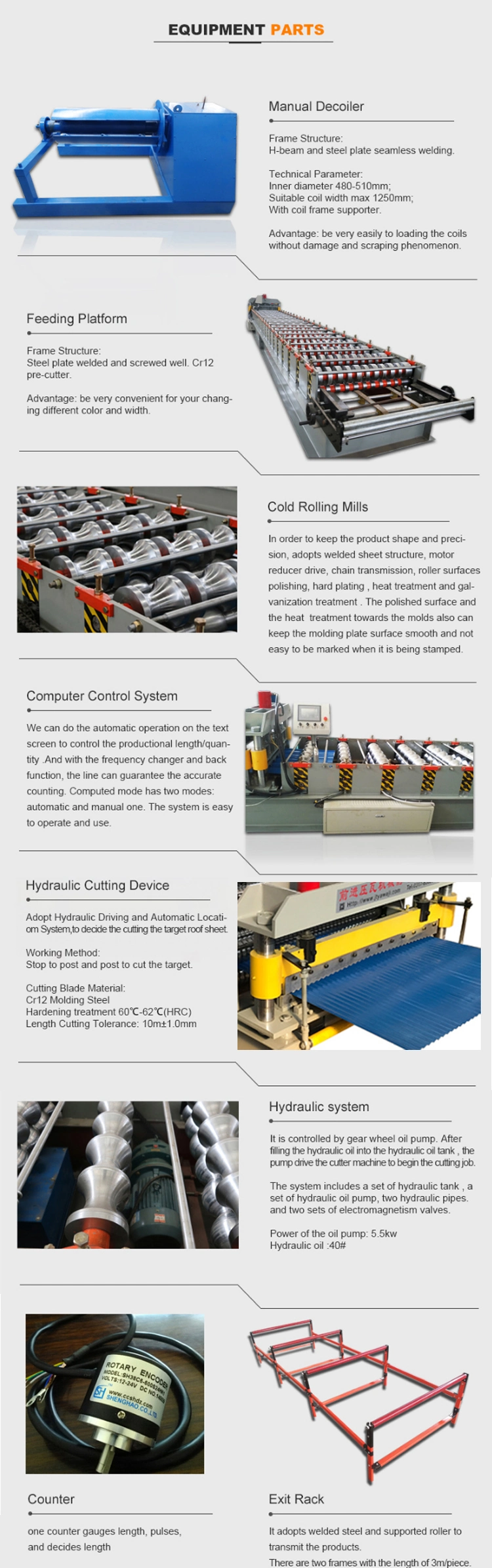

Products showing

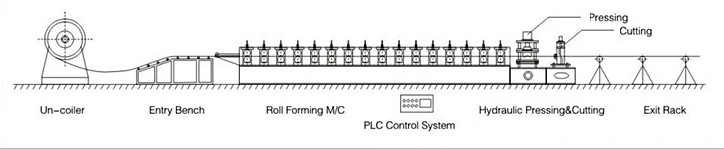

Decoiler-----feeding----- leveling ----- cutting -----roll forming ----- punching ----- output table

Packaging & Shipping

1. roll forming machine and uncoiler are nude packing (If you need, we can also packed it with water-proof plastic)

2. PLC control system and motor pump are packed with water proof paper,spare parts in carton box.

3.One set of machine needs a 40' container to shipping.

Our Services

1. Warranty :One year,and we will provide technical support for whole life of the equipment.

2. Delivery time: Within 35 days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.

FAQ

1

Q:Are you manufacturer? A:Yes,we are manufacturer for cold roll forming machine over 12 years.

2

Q: if you can accept OEM? Design and manufacture according our photo.A: Yes, we can accept OEM,we owned expert engineer team, professional design CAD drawings and use famous brand components according your demands.

3

Q:What's the warranty for your machine?

A: we provide 2years guarantee and provide lifetime technical support.

4

Q:How many workers is needed for the machine operation A: One worker is enough, the machine use automatic PLC control system.

5.Q. Do you have after sales support?

A: Yes,Our engineer can supply remote-video technical support and online support teach your worker.

6. Q.Can you be responsible for transport?

A.Yes,we owned expert export team, we can arrangement for you to your destination port or address.

7.

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands,such as design,technical parameter, delivery flow etc. At the same time, we can supply invitation letter for your visit our factory and showing the machine operation for you .

8

Q: What is the after- sale service?

A: we will supply lifetime technical support,quick-wear parts within 2years,Also can provide field maintenance and repair service .

9

Q:Any other service?

A: We can help you purchase raw material for machine,help you check ship date,update for you ship date etc

10

Q:Any certificationA:Yes, we have SGS ISO certification.

11

Q:How do your machines compare with other big companies in this market?

A:our factory machine only export, quality and standard are conform to world-standard, and we have good manufacture-experience for different country demands.

12

Q:Will you deliver the right goods as ordered? How can I trust you?

A: Yes, of course, reputation is our company's life, our factory owned alibaba golden-diamond supplier,SGS certificate and CE certificate.

13

Q:How to visit your company?Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we pick up you.

14

Q: How can we be assured that you will deliver us quality machine with spare parts?

A: welcome visit our factory at any time, check all our raw material,worker quality,factory feeling etc.

15.

Q:Can you provide some spare parts?

A: Yes, of course. We will loading some quick-wear parts together with the machine.

16

Q: Does one machine can only produce one style panel profile?

A: Not exactly, we have double or three layer machine, one machine can produce 2 to 3 profiles.

17.

Q:Payment Terms.

A: we can accept TT and TT+LC.

18

Q:What information you need prepare before quote me?

A: best send us your profile and raw material detail, or we can custom-made according your demands.

19

Q: I am new in this field, do not know about the machine and do not know how to operate it.

A .The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.

If you need, we can also send the technician to your factory to fix the machine and train your workers.

20

Q:What is included in the machine?

A.The whole line includes a manual decoiler, roll forming machine, received goods table and spare parts box.

The whole line includes a manual decoiler, roll forming machine and received goods table. when you get the machine in your factory, you just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.(Based on your local use voltage,some use 2phase )

21. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 100 USD per day per person (from departure of our factory, until engineer back to our factory). You also need to take care of his safety.

22

Q:Is the machine automatic?

A: Yes,it can be manual or automatic

Company Information

Tianjin Haixing Imp&Exp company are specializing in the production of all kinds of Aluzinc rib roofing sheet roll forming machine,glazed roof making machine, double roof making machine, floor deck machine,curve roof machine,ridge cap roof forming machine, different sizes roofing sheet, PPGI/ GI,Alu-Zinc steel coils ,Galvanized steel coils, Galvanized steel sheet,Galvalume steel coils/sheet, cold/ hot rolled sheet/coils,professional service and favorable price, satisfied with the quality,welcome to every customers come to visit and buy !

Related machinery

Prev: Automatic Curving Machine for Standing Seam Roofing with Panel

Next: Automatic Adjusted Standing Seam Roof Panel Curving Machine

Our Contact

Send now